SID212EVO AdBlue Faults Explained: The Complete Ford EcoBlue Guide (2026)

SID212EVO runs the AdBlue (SCR) logic on many Ford EcoBlue diesels. Most “AdBlue warning” problems come from pressure, quality, or SCR efficiency checks failing. If you see a no-start countdown, diagnose the right system early so you don’t keep replacing parts that won’t clear it.

Searching “SID212EVO AdBlue faults” usually means one of three things has happened. Your van has thrown a fault code and started a countdown. You’re in limp mode and you don’t know if it’s DPF or AdBlue. Or you’ve already replaced a pump or NOx sensor and the warning still returns. This page is the master guide. It explains what SID212EVO is, how the SCR system works, which fault codes matter, and what actually fixes them.

Don’t wait for it to hit zero. Once it reaches 0 miles, many vehicles will block starting. If you need the quickest route, start here: No-start countdown help.

Want the wider comparison between emissions systems? See: DPF vs AdBlue faults.

What is SID212EVO?

SID212EVO is an ECU type used on many modern Ford diesel vehicles, including Ford EcoBlue engines. The ECU controls far more than fuelling. It manages torque limits, boost requests, EGR strategy, and critically, the emissions systems that trigger AdBlue warnings and no-start countdowns.

When you see “AdBlue fault”, the dashboard message feels like a simple fluid issue. In reality, the ECU runs checks. It measures sensor data, compares expected values, and decides whether to show a warning, reduce power, or start a countdown to start prevention. That’s why topping up sometimes does nothing. The ECU doesn’t care that the tank is full if the test logic still fails.

SID212EVO faults are rarely “random”. The system is reacting to a failed check. The quickest fix comes from identifying which check failed, then proving it’s corrected so the ECU stops re-triggering the fault.

Symptoms → likely cause → best next step

This table is the quickest way to stop guesswork. Start with what you see on the dash, match it to the most likely root cause, then take the next step that actually moves you forward.

| What you notice | Likely cause | Best next step |

|---|---|---|

| No start in 500 miles (or similar) | SCR compliance check failing, often pressure or efficiency | Pull exact codes (P20E8, P204F, P20EE, P207F). Don’t buy parts until you know which check failed |

| AdBlue full but warning remains | Quality logic (P207F) or pressure/flow issue | Check AdBlue age/contamination and confirm pressure prime behaviour |

| Limp mode + emissions light | AdBlue and DPF can overlap | Compare live NOx data vs DPF load and regen behaviour to separate systems |

| P20E8 repeats after pump replacement | Restriction, crystallisation, or injector/line issue | Inspect injector, flush lines, check for crystals around dosing point and tank neck |

| P20EE returns after NOx sensor swap | Exhaust leak, sensor drift under load, or injector spray/catalyst logic | Verify upstream/downstream NOx behaviour under load and check for small exhaust leaks |

How SCR works (AdBlue) on Ford EcoBlue

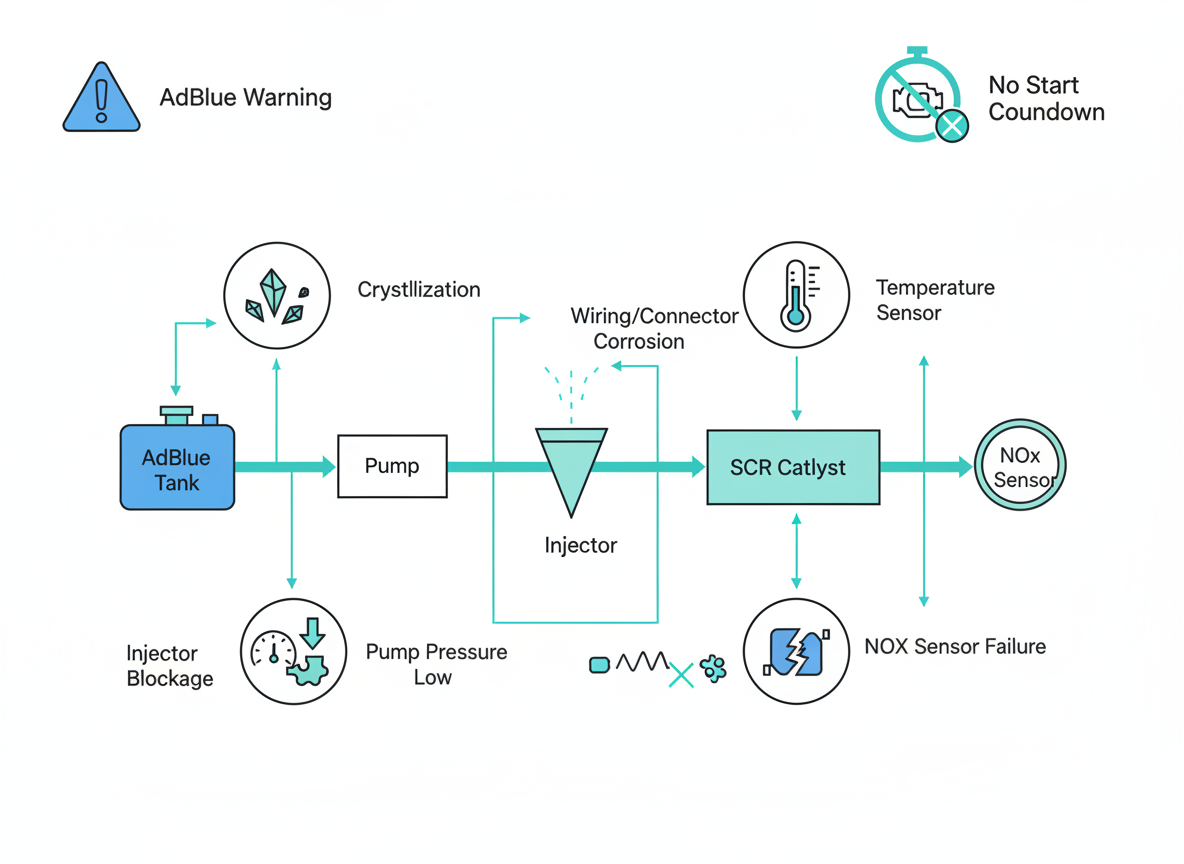

SCR stands for Selective Catalytic Reduction. It’s the part of the exhaust system that reduces NOx emissions. AdBlue (a urea solution) gets injected into the exhaust stream. Under heat, it helps convert harmful NOx into nitrogen and water vapour. The system works well when the components agree with each other. Faults happen when one piece of the chain fails and the ECU sees the test result drift out of range.

NOx sensors

The system uses upstream and downstream NOx readings to judge whether the catalyst is reducing emissions. Drift, slow response, or wiring issues can make the ECU think SCR has failed.

AdBlue pump and lines

The pump must supply stable pressure. Low pressure, weak prime, or pressure drop can trigger P20E8 and start a countdown if it persists.

Dosing injector + SCR catalyst

The injector must spray correctly. Poor spray patterns, partial block, or leaks can trigger efficiency and performance faults.

How SID212EVO decides: warning, limp mode, or countdown

SID212EVO doesn’t just store a code. It runs checks and applies consequences. It detects a fault, watches whether it persists across drive cycles, then escalates based on compliance logic. That escalation is why a vehicle can feel “fine” for days, then suddenly display a countdown.

- Warning only: early-stage issues, intermittent plausibility problems, mild dosing deviation.

- Limp mode / reduced power: the fault persists or torque limits protect the emissions strategy.

- No-start countdown: the ECU believes emissions compliance cannot be met and starts enforcement.

Replacing a part because the code “mentions it” without proving the system check passes afterwards. The ECU repeats the same test. If it still fails, the warning returns.

Most common SID212EVO AdBlue fault codes (and what they usually mean)

Use this overview to orient yourself. Then jump into the exact code page so you follow a focused test path and don’t get dragged into parts roulette.

| Code | What it means | What usually causes it | Where to go next |

|---|---|---|---|

| P20E8 | Reductant pressure too low | Weak pump, pressure drop, restriction, crystallisation, line issues | SID212EVO P20E8 guide |

| P204F | Reductant system performance | Dosing behaviour not matching expected performance, sensor plausibility, flow issues | SID212EVO P204F guide |

| P207F | Reductant quality performance | Contaminated/old AdBlue, incorrect concentration, quality logic triggered | SID212EVO P207F guide |

| P20EE | SCR efficiency below threshold | NOx sensor drift, injector issues, exhaust leaks, catalyst efficiency logic | SID212EVO P20EE guide |

Dashboard wording varies by model and year. What matters is the stored code, the trigger conditions (freeze-frame), and whether the fault repeats after a verified fix.

If you’re seeing other platform SCR faults, this guide can help as a comparison: Peugeot P20EE fault code fix.

SID212EVO no-start countdown logic: why topping up often fails

The no-start countdown is where most people lose time and money. It shows as “no start in 500 miles”, “engine start impossible in X miles”, or similar wording. Many drivers top up AdBlue, clear codes, and hope it disappears. That only works if low fluid caused the warning and nothing else failed.

The ECU triggers a countdown because a compliance check keeps failing. Even with a full tank, the ECU can still see low pressure, poor dosing behaviour, quality plausibility failures, or low SCR efficiency. Until the ECU sees the check pass, it keeps the fault pathway alive.

- Pressure check fails: P20E8 and related prime/pressure behaviour faults.

- Quality logic fails: P207F when concentration plausibility or dosing calculations drift.

- Efficiency logic fails: P20EE when NOx reduction stays below threshold.

- System performance fails: P204F and related reductant performance decisions.

Need the dedicated emergency guide? Ford SID212EVO no-start countdown.

SID212EVO limp mode: is it DPF or AdBlue?

Limp mode is where people waste money. You see reduced power and assume DPF. Or you see an AdBlue warning and replace SCR parts, when DPF load is the real issue. You can usually separate the two by looking at the message type, regen behaviour, and which codes are present.

| What you notice | More likely AdBlue / SCR | More likely DPF |

|---|---|---|

| No-start countdown appears | Very common (SCR compliance enforcement) | Uncommon |

| AdBlue / emissions warning returns after clearing | Common with P20E8, P207F, P20EE | Possible, but DPF codes usually appear too |

| Regeneration messages or fans after shut-off | Less common | Common when DPF load is high |

| Smoke / soot under load | Not typical | More typical (depending on failure mode) |

| Codes mention reductant, NOx, SCR | Strong indicator | Weak indicator |

Use the dedicated comparison guide before you spend money: SID212EVO limp mode: DPF or AdBlue.

Common component failures on SID212EVO (and what they look like)

Online advice often jumps straight to “replace the pump” or “replace the NOx sensor”. Sometimes that’s right. But on SID212EVO, faults often chain together. A restricted injector can trigger efficiency faults. A weak pump can trigger pressure faults that then trigger efficiency faults. A wiring issue can mimic a sensor failure.

AdBlue pump failure

- Weak prime behaviour or pressure drop under demand.

- P20E8 faults that clear briefly and return after driving.

- Often worse in cold weather or after sitting.

Full guide: SID212EVO AdBlue pump failure.

NOx sensor drift or plausibility issues

- P20EE repeats after other fixes.

- Readings don’t respond as expected under load.

- Upstream/downstream relationship looks illogical.

Full guide: SID212EVO NOx sensor faults.

Heater faults and crystallisation

- Crystals form in lines, injector, or tank neck.

- Flow restriction that looks like pump failure.

- Cold weather exposes borderline components.

Background: AdBlue fix options.

Wiring and connector issues

- Intermittent faults after rain or vibration.

- Sensor faults that don’t match real behaviour.

- Fault returns quickly after clearing, with no pattern.

This is why live data and freeze-frame matter. It stops guesswork.

Why SID212EVO faults keep coming back after repairs

A part gets replaced. The warning clears. A week later it returns. That doesn’t always mean the new part is faulty. It usually means the ECU test still fails, or a linked failure remains in the system.

- Wrong part replaced first: the code name leads the repair, not the test result.

- Crystallisation not dealt with: new parts fitted into restricted lines or a blocked injector.

- Reset done without verification: the ECU re-runs the check and fails again.

- NOx sensors “look fine” at idle: but drift under load, so the efficiency check fails on the road.

- Exhaust leaks ignored: small leaks can upset sensor readings and trigger efficiency faults.

A list of suggested parts with no proven test result at the end. The goal is simple: fix the cause, then prove the ECU check now passes.

Can you reset SID212EVO AdBlue faults without fixing the cause?

You can sometimes clear a warning temporarily. But if the check still fails, the fault returns. On SID212EVO, the system often needs a verified repair and a reset procedure that matches the ECU’s logic. That’s why quick code clearers have mixed results.

When a reset can help

- The issue was low fluid and no other faults exist.

- A minor plausibility fault occurred once and does not repeat.

- A repair is complete and you need the ECU to confirm normal operation.

When a reset will not help

- Pressure, quality, or efficiency checks still fail.

- A countdown started because compliance can’t be met.

- You clear the code and it returns within a day or drive cycle.

Use the dedicated guide: Reset SID212EVO AdBlue faults.

Real-world mini cases (problem → code → fix → outcome)

These are the patterns we see most. One fault triggers another. A repair clears the dash, but the next compliance test fails and the message returns. The winning move is proving the check now passes, not just swapping the part the code mentions.

Problem: “No start in 500 miles” appeared after the vehicle sat for a few days.

Codes: P20E8 + P204F.

What we found: Pressure built at prime, then dropped during dosing demand. Crystals also showed around the dosing point.

Fix: Replace pump, flush line, clean dosing path, confirm stable pressure under demand.

Outcome: Countdown cleared and did not return after multiple drive cycles.

Problem: P20EE kept returning even after a NOx sensor replacement.

Codes: P20EE (repeat), occasional performance-related pending faults.

What we found: Small exhaust leak upstream of the downstream sensor, skewing the efficiency calculation.

Fix: Repair leak, verify upstream/downstream NOx behaviour under load, clear and confirm the test passes.

Outcome: Efficiency test passed and the fault stayed cleared.

SID212EVO AdBlue fault FAQ

These questions target the exact long-tail searches people type when they’re staring at a countdown. If one matches your situation, use it as your starting point before you spend money.

Usually yes, until the countdown reaches zero. After that, many vehicles will block starting. If you rely on the van for work, treat it as time-sensitive and diagnose early.

Often yes at first, but you may get reduced power, a countdown, or repeated warnings. The more it repeats, the more likely you’ll end up with start prevention.

Only if the tank level was the only cause and no compliance check failed. If you have pressure, quality, or efficiency faults stored, topping up won’t clear them.

Because SID212EVO isn’t measuring “how full the tank looks”. It’s running checks. If pressure is low, dosing is wrong, quality plausibility fails, or efficiency stays below threshold, the warning remains.

They are different problems. P20E8 is supply-side (pressure). P20EE is performance-side (SCR efficiency). P20E8 can cause P20EE if dosing becomes inconsistent.

Pump faults show unstable pressure behaviour and often repeat around prime or dosing demand. NOx faults show odd upstream/downstream behaviour, especially under load, not just at idle.

Because the ECU repeats the compliance test. If it still fails, it re-triggers the warning. Crystallisation, leaks, wiring faults, or the wrong part replaced first are common reasons.

Yes. Updates can tighten monitoring thresholds. That can expose borderline sensors, weak pumps, or injector issues that previously “just about passed”.

SID212EVO software updates: why new SCR faults appear afterwards

Some Ford EcoBlue owners notice a pattern. The vehicle was fine, then after a software update or dealer work, new SCR faults begin. That doesn’t always mean the update “broke” the van. It often means the calibration changed thresholds, monitoring became stricter, or the ECU now flags a borderline component that used to pass.

Efficiency monitoring is a good example. If the ECU tightens the allowed NOx reduction window, a sensor drifting slightly may now trigger P20EE. If dosing monitoring becomes stricter, a weak pump or restricted injector may now trigger P204F or P20E8 sooner.

- Don’t guess parts from the first code description.

- Use live data to confirm whether a component is failing under load.

- Check for linked faults that cause the main code (pressure → efficiency, quality → efficiency).

Full breakdown: SID212EVO software updates guide.

What to do next if you have a SID212EVO AdBlue fault

If you want the fastest outcome, keep it simple. Get the exact fault codes. Confirm which compliance check is failing. Avoid guessing parts. If you’re already in a countdown, treat it as time-sensitive because start prevention can leave you stranded.

- Read the codes properly and note any of these: P20E8, P204F, P207F, P20EE.

- Check if a countdown is active. If yes, don’t delay.

- Use the exact guide so you don’t get dragged into overlap:

- Book diagnosis if it keeps returning or you’re in countdown, so the fix is verified, not guessed.

We diagnose first, then fix what has actually failed, on your driveway or at your workplace.

You can also browse related services: Our services, plus Ford AdBlue help and Car & van AdBlue repair.